Quality within

0.6% of vessel COA

Increased blend

values by over 30%

The Challenge

A multi-mine Coal exporter in South Africa needed a “Day of Operations” system to track port inventory and optimize the delivery of coal onto vessels. To make informed and accurate decisions required daily live data updates of train arrival status, coal quality lab results, inventory reconciliation, vessel berthing and vessel ETA.

Coal transport consisted of railing multiple grades from each of several mines, with tracking and management of coal qualities including ash, volatile matter, sulphur, moisture and NCV.

The Solution

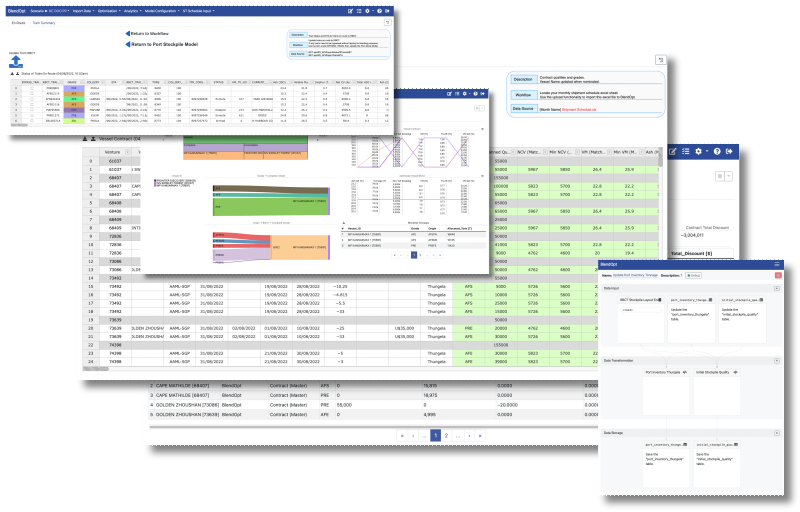

Using BlendOpt the client was able to monitor the stockpile levels and qualities using regularly updated data from the coal terminal, with the predicted qualities falling within 0.6% of the vessel COA. The port management team were able to view new tippings to the stockpiles, with validation showing when the tipping qualities were outside grade specifications and therefore presented a quality risk. The inbuilt Optimisation module of BlendOpt also removed the requirement for trial-and-error blend development. BlendOpt's highly configurable ETL pipeline GUI was used to rapidly configure and integrate the client's data sources within the application.

The Value Unlocked for our Client

By selecting high discount grades to add to the blend, that would not normally be considered during manual blend development, BlendOpt provided a solution where the client was able to increase the value of some of their blends by over 30% with the blends still meeting the contractual requirements.

BlendOpt's ensured transparency and confidence in daily decisions with significant impact to client cash flow, while data integration and live dashboards allowed non-technical users to rely on BlendOpt as a single source of truth for viewing and understanding the client's port operations.

Get started today—see how BlendOpt can streamline your planning and scheduling!

Do you optimize product placement into the market?

Do you know when Demurrage adds value (can you spot “value justified” demurrage)?

Do you know in what situations your stockpile quality models increase contract rejection risk?

Does your planning software require stable operations, predictable markets, consistent orebodies?

Can you run scenarios to understand your options?

Does your tactical scheduling software automatically synchronize with your longer term planning tools?

Do your schedules reflect conditions on the ground?

Are your schedules tossed in the bin on day 1?